In-Mold Decorations: Integrating Layout and Manufacturing Excellence

In-Mold Decorations: Integrating Layout and Manufacturing Excellence

Blog Article

Understanding In-Mold Decorations: Methods, Patterns, and Ideal Practices for Ideal Outcomes

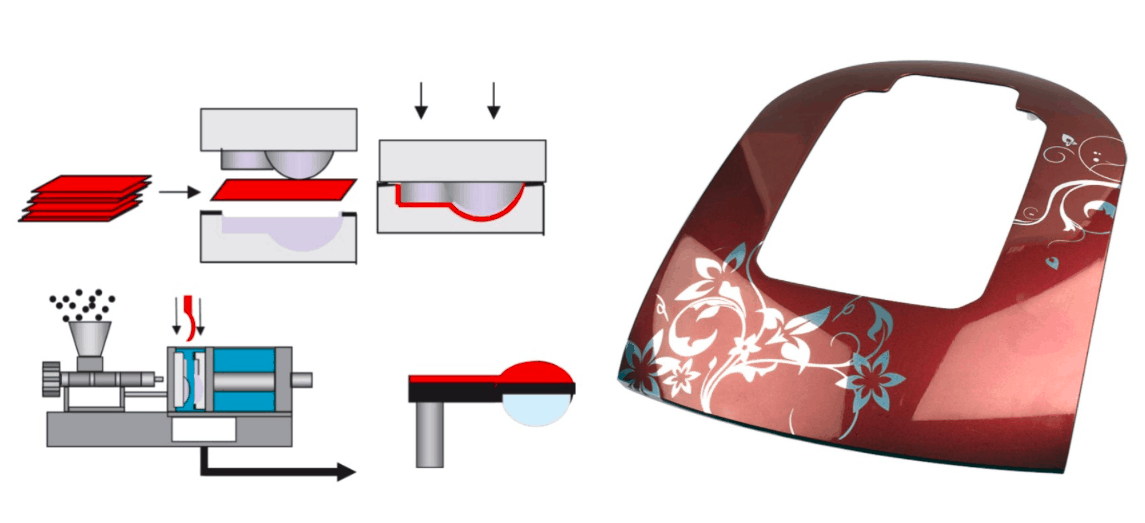

In the realm of production, the art of in-mold designs stands as an essential facet of product style and manufacturing. As sectors continuously seek innovative means to boost aesthetic appeal and functionality, understanding the intricacies of in-mold designs has become a crucial ability. From choosing the ideal materials to integrating sophisticated layout fads, the journey towards accomplishing optimal lead to this domain is complex. By diving right into the methods, patterns, and ideal practices that underpin successful in-mold design processes, businesses can unlock a world of possibilities that not only elevate the aesthetic attraction of their products but likewise improve manufacturing performance and boost consumer engagement.

Material Option

Product choice is a vital facet of mastering in-mold designs, as it directly impacts the top quality and longevity of the last product. When choosing products for in-mold designs, it is necessary to consider factors such as compatibility with the molding procedure, the desired visual end result, and the ecological problems the product will face.

In addition, the chosen product should possess great attachment homes to make certain that the decor adheres firmly to the substratum during the molding procedure. Attachment between the decor and the material is critical for protecting against delamination and guaranteeing resilient visual charm. Furthermore, products with high heat resistance are liked for in-mold designs, specifically for products that will be exposed to elevated temperatures throughout their lifecycle. By thoroughly selecting the ideal material for in-mold decors, producers can boost the total high quality and sturdiness of their items, fulfilling the assumptions of both customers and end-users.

Design Development

A crucial consider advancing the field of in-mold decors is the constant expedition and application of style development strategies. Layout advancement plays an essential function in boosting the visual charm, performance, and overall top quality of items made using in-mold design procedures. By integrating ingenious layout elements, suppliers can distinguish their items in the marketplace, bring in consumers, and stay ahead of competitors.

One of the crucial elements of design innovation in in-mold decors is the combination of elaborate patterns, appearances, and graphics that were previously testing to attain with standard design techniques. Advanced innovations such as 3D printing and electronic style tools make it possible for developers to create complicated and detailed styles that can be flawlessly moved onto shaped components. In addition, the use of dynamic shades, metallic coatings, and unique impacts like gloss or matte textures can further raise the aesthetic appeal of in-mold decorated items.

Furthermore, style innovation prolongs beyond aesthetics to encompass functional enhancements such as ergonomic shapes, incorporated features, and personalized aspects that provide to details user requirements. By embracing style advancement, suppliers can open new opportunities for product, creative thinking, and customization differentiation in the competitive landscape of in-mold decors.

Production Efficiency

Efficient production processes are crucial for equating the cutting-edge styles established in the field of in-mold decors right into premium finished items that satisfy market demands and customer assumptions. In the world of in-mold decorations, production efficiency encompasses numerous crucial elements that add to the overall success of the manufacturing process.

Automation not only accelerates the production process however additionally enhances accuracy and repeatability, leading to an extra uniform and high-grade end product. Overall, an all natural strategy to manufacturing performance is extremely important in optimizing the possibility of in-mold decor techniques and attaining optimal results in the affordable market landscape.

Quality Assurance Measures

What are the vital techniques for making sure stringent high quality control actions in the realm of in-mold designs? Quality control procedures are vital check this in in-mold decoration procedures to make certain the manufacturing of top notch and perfect ended up items.

Using innovative innovations such as automatic evaluation systems can likewise enhance the quality control process by supplying this hyperlink trusted and exact information for analysis. These systems can detect flaws that might be missed by manual examinations, consequently boosting total item quality and consistency.

Normal training and growth programs for employees involved in the in-mold design procedure can likewise add to maintaining high-grade standards. By enlightening staff on best techniques, quality expectations, and the value of focus to detail, firms can promote a society of high quality consciousness throughout the organization.

Customer Charm

To boost the bankability of in-mold decoration items, recognizing and catering to consumer preferences play a vital function in determining their allure and success. Providing personalization options such as individualized designs, shade variants, and textural components can significantly boost the allure of in-mold decoration items.

Conclusion

In-mold decors use a versatile and efficient way to enhance product appearances. By carefully picking materials, accepting ingenious layouts, enhancing manufacturing procedures, implementing quality control steps, and focusing on customer allure, producers can accomplish optimal results. It is important for companies to continuously adjust and enhance their techniques to remain competitive in the market. In-Mold Decorations. Mastering in-mold decors needs a holistic approach that thinks about all aspects of the manufacturing process to guarantee success.

In the world of production, the art of in-mold click over here now decorations stands as a critical element of product layout and production. Layout advancement plays an important role in enhancing the aesthetic appeal, capability, and overall high quality of products manufactured making use of in-mold design processes.One of the essential facets of layout technology in in-mold decors is the combination of elaborate patterns, structures, and graphics that were previously challenging to achieve with conventional design methods.Efficient production processes are crucial for converting the ingenious styles established in the area of in-mold designs into premium ended up products that meet market demands and consumer expectations. Using customization choices such as personalized layouts, color variations, and textural aspects can substantially enhance the allure of in-mold decor products.

Report this page